The Naissance d’une Montre 3 Ferdinand Berthoud’s Guillaume Balance Was The Secret Weapon Of Observatory Chronometers

Difficult and expensive to make, the Guillaume balance was designed to be the last word in precision timekeeping.

The Naissance d’une Montre 3 Ferdinand Berthoud has been getting quite a bit more attention from enthusiasts and the watch press than you might expect from a very, very niche watch that sells for a cool CHF 850,000 and which will be produced at the glacial pace of two watches per year. The price itself, of course, has something to do with it – superlatives always make for attention grabbing headlines – but there are plenty of watches out there which cost on the far side of three quarters of a million bucks and which don’t generate as much discussion as the Naissance d’une Montre 3. This is the third of the Naissance d’une Montre watches, which are produced in collaboration with the Time Aeon Foundation, which was founded to make watches using only classic, manual watchmaking methods.

The real hook with the Naissance d’une Montre 3 isn’t just that it’s incredibly expensive, it’s that the expense is hand in glove with how the watch came to be, and how they’ll be made. Essentially, the Naissance d’une Montre project as a whole began as an exercise in “preserving traditional watchmaking expertise,” and they mean tradition – each Naissance d’une Montre watch is made by hand, using only traditional watchmaking methods. This doesn’t mean no electricity – lathes and drills are used for making the watches which are electrically powered – but it does mean no CNC machines and no spark erosion machines, which means many parts are roughed out on manually guided machines, or simply cut from raw materials using piercing saws that would be familiar to any watchmaker from a century ago or more.

It also means that no automated milling machines of any kind were used – automatic, cam-guided lathes were a mainstay of mass produced industrial watchmaking long before computer guided multi-axis machines were introduced – and making a watch in this way is monumentally time and labor intensive. The problem is made orders of magnitude more difficult when you aren’t just undertaking the task of making a watch by hand – you’re trying to make a watch to the highest possible traditional workshop standards as well.

The Naissance d’une Montre 3 has some very unusual features in a modern watch, the most conspicuous of which is the fusée and chain.

The fusée is older than actual watchmaking – there are sketches of fusée cones in the notebooks of Leonardo da Vinci, and the first use of a fusée that we know of was in windlasses for winding up crossbows.

The fusée is a constant force mechanism. Mainsprings tend to deliver too much torque at the beginning of their power curve and too little at the end. In a watch with a fusée and chain, the chain is unwound from the fusée cone as it’s pulled onto the mainspring barrel, with the smallest circle of the fusée used at the start, and the largest at the end of running time. It works the same way as gears do on a ten speed bicycle – the mechanical advantage of the mainspring gets larger and larger as the fusée cone gets bigger in diameter, just as the largest gear on a ten speed is the one used for hill climbing.

The chain and fusée mechanism was essential in precision watchmaking for several reasons. First, early escapements like the cylinder and verge were so-called frictional rest escapements, in which the impulse surfaces are in constant contact with the balance. Unless mainspring torque is absolutely constant, balance amplitude will fluctuate wildly depending on mainspring torque, with the period of the balance fluctuating as well. The addition of a balance spring lessened the problem, as did the adoption of detached escapements like the lever and detent escapements, but the fusée remained in use in many high precision clocks and watches – most notably, in marine chronometers, for which Ferdinand Berthoud was famous – right up until the mid-20th century.

The fusée and chain also presents another problem, which is that when you wind a watch with a fusée, you are winding the chain off the mainspring barrel and onto the fusée cone. This means that the fusée is turning in the opposite direction it needs to in order to power the going train, and the watch will stop. This problem was first solved by John Harrison, who developed a maintaining power mechanism that uses a circular spring inside the movement great wheel, on which the fusée rests and which is the first gear in the going train. The parts count for the fusée chain is impressive – 258 links, 191 pins, all made and assembled by hand – but the larger technical history which the fusée and chain represents underscores the relationship of the Naissance d’une Montre 3 to Ferdinand Berthoud’s career as a maker of high precision timekeepers as well.

A number of construction details are deliberate anachronisms, including the use of friction fit pins on the mainspring barrel and fusée; such pins were replaced by threaded fasteners – screws – in watchmaking, as screw-cutting machines became more and more widespread at the end of the 18th and beginning of the 19th centuries. I can’t recall seeing such pins used in any other modern watch, and the click wheel and click on the mainspring barrel are equally reminiscent of watchmaking in its earliest days.

What part of the Naissance d’une Montre 3 Ferdinand Berthoud interests you most is a matter of taste, of course, but one feature which I think deserves (a lot) more attention than it has gotten, is the balance.

The balance is of a type which hasn’t been made by anyone in at least sixty five years (again, as far as I know; it may have been even longer than that). This is what’s called a Guillaume balance, after its inventor, Charles Guillaume, who won the Nobel Prize in 1920 for his discovery of the temperature invariant properties of nickel steel alloys. The Guillaume balance was designed to solve a basic watchmaking problem: as temperature changes, the rate of a watch will also change, thanks to temperature induced changes in the elasticity of the balance spring. Typically, a balance spring will become less and less elastic as temperature increases, which will tend to cause the watch to run slower; this problem is compounded by the tendency for balances to expand, which increases moment of inertia and also produces a slow down in rate.

Temperature Effects On Balance Springs, And Temperature Compensation

This effect was known as early as the early 18th century and became obvious to watchmakers as balance springs came into regular use. Prior to the invention of the balance spring (by the English scientist Robert Hooke, and, in its spiral form, by the Dutch horologist and physicist Christaan Huygens, in 1675) watches and clocks had not been accurate enough for temperature effects to be noticeable.

In 1773, Ferdinand Berthoud made the first known attempt to describe the changes in rate due to temperature in terms of the various parts of the oscillating system. He found that in his test movement, there was a loss of 393 seconds in 24 hours if the temperature was changed from 33.75º Celsius to 92º Celsius. Of this total, Berthoud attributed 62 seconds to the expansion of the balance, 312 seconds to the loss of stiffness in the spring, and 19 seconds to lengthening of the balance spring.

Temperature compensation was first applied to watches by John Harrison, and a balance which compensates for the changes in the elasticity (and length) of the balance spring came shortly thereafter, having first been developed by Pierre LeRoy in 1765, and then further developed by John Arnold and Thomas Earnshaw in England.

The compensating balance is made of two strips of metal with different coefficients of expansion.

The outer strip is brass, and the inner is carbon steel. The rim of the balance is cut right next to the arms. As temperature rises, the different rates of expansion of brass and steel cause the free ends of the balance rim to bend slightly inward. This counteracts the loss of stiffness and expansion in length of the balance spring, and you can control the amount of compensation by moving the screws on the rim, and/or by adding washers under them or undercutting the undersides of their heads in order to remove metal. The reduction in diameter of the balance tends to produce a gain in rate, which counteracts the loss in rate produced by the reduction in stiffness of the balance spring.

Watches with bimetallic compensating balances can be adjusted to keep almost perfect time, although to get the most out of them, careful adjustment is necessary as any adjustments for temperature compensation may also upset the poise of the balance and require further adjustments to the attachment points of the balance spring, or the poise of the balance, or both. As this may in turn affect temperature compensation, you can imagine how much expertise and patience adjusting such a balance required; for observatory trials, watches might be adjusted for weeks or even months before being submitted.

As is so often the case in watchmaking, an improvement in precision revealed yet another problem.

The basic problem with this system, is that the change in balance diameter is more or less linear. The change in balance spring elasticity, however, is not. What horologists eventually noticed was that if you adjusted a balance for temperature compensation, you would get perfect cancellation of temperature effects at two points, but with a gaining effect in between those two temperatures and a losing effect to the right and left on a graph:

This error is called, “middle temperature error” for obvious reasons – it’s also sometimes called “secondary error” as it’s a secondary or residual error from a compensating balance paired to a steel balance spring.

The Guillaume balance was, like the standard bimetallic balance, designed to compensate for the effects of temperature on the balance spring. However, instead of steel, the Guillaume balance used a nickel-steel alloy called Anibal, which Guillaume had discovered in 1899. Such balances were used in many famous high precision watches, including the Rolex Kew Observatory Class A chronometers, and the Zenith 135-O observatory caliber, which won over 235 awards for precision, and which took first prize at the observatory in Neuchâtel five times in a row, from 1950 to 1954. Guillaume balances essentially eliminated middle temperature error, making them indispensable elements of observatory competition watches (although they were sometimes used in production watches as well).

The Guillaume balance was, however, never really mass produced – it required considerable care to make and even more to adjust, and for most of the 20th century, it was sort of the F1 engine of precision timekeeping – delivering the highest possible performance, but mostly impractical for every day use on a large scale.

The standard bimetallic balance was replaced for general use in watches, by Nivarox alloy-type balance springs, and monometallic beryllium bronze balances, made of the alloy called Glucydur. Nivarox balance springs can be made to compensate almost perfectly for the expansion of Glucydur balances as temperature increases, and they are much more resistant to magnetism than the steel balance springs necessary in Guillaume balances. While the Nivarox-Glucydur combination still retains some residual temperature error, it’s insignificant enough for the combination to enable watchmakers to produce chronometers on an industrial scale.

The most recent uses of Guillaume balances have pretty much been in new old stock movements, like the Voutilainen Chronomètre 27. Prior to this, the most recent use I’ve been able to find of a Guillaume balance is in an Omega 30mm observatory movement, which was submitted to the observatory competitions in 1967. Considering the date, it seems likely that a properly adjusted Guillaume balance could still, under the right conditions, best a Nivarox and Glucydur combination but the advantage if any would be slight and would require the hands of a master adjuster.

The Naissance d’une Montre 3 Guillaume Balance

The Guillaume balance in the Naissance d’une Montre 3 is therefore – and again with the caveat, “as far as I know” the first of its kind in nearly seventy years. Ferdinand Berthoud had to reverse engineer the techniques necessary for making one – I don’t think there is anyone left who actually knows how to make one from scratch although I would bet really money that if you asked Philippe Dufour (who is a member, lest we forget, of the Time Aeon Foundation) how to go about it, he might know.

This is not the first compensating balance since the 1960s, by the way; watchmaker Karsten Frasdorf showed a compensating balance in 2019, which was actually paired with a Glucydur balance and Nivarox spring, and which was intended to allow a watchmaker to make fine temperature adjustments for any residual temperature error. But Guillaume balances? They are so rare as to be unknown in mechanical horology since before the Quartz Crisis.

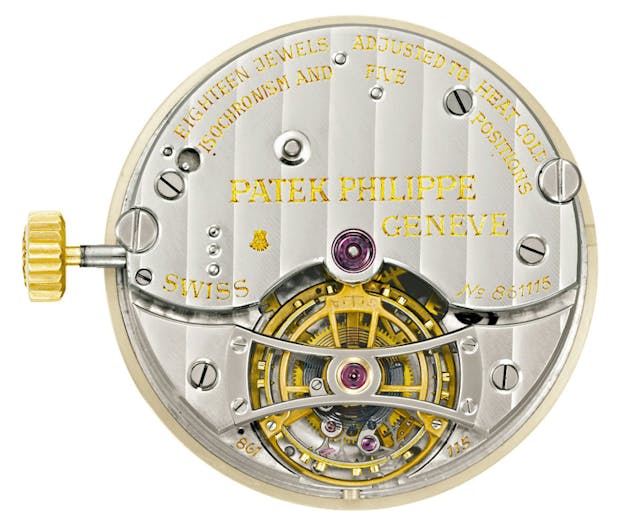

And here it is. You’ll notice right away that the cuts in the balance are noticeably further away than they would be in a standard bimetallic compensating balance, and also that there are two large, moveable weights; these are the weights for changing temperature compensation; the balance in fact looks very much like one you’d find in a marine chronometer. I assume that the balance has been poised the old fashioned way as well, which is to use the poising screws spaced along the rim (modern Glucydur balances are typically laser cut on their undersides to adjust poise). The balance spring is blued carbon steel, and the color is not cosmetic; a blue temper gives optimum stiffness for the balance and is a necessary counterpart to the physical properties of a Guillaume balance. The balance spring has a mathematically correct Phillips outer terminal curve (the curve is named after the French mathematician Edouard Phillips, who put the Breguet overcoil on a solid theoretical math foundation in the 1860s).

The balance spring’s outer coil is held in place by the non-moveable stud held in place by a very highly polished screw and two steady pins, just to the left of the very unusual antishock spring and diamond endstone (the lower endstone is diamond as well). Each balance spring and Guillaume balance in the Naissance d’une Montre 3 have to be custom made and adjusted to each other, and the results are recorded in the official chronometer bulletin issued for the first watch by the COSC.

The Naissance d’une Montre 3 exceeds COSC chronometer certifications significantly; the COSC standard mean daily rate variation for 30mm movements is -4+6, with the Naissance d’une Montre 3 Ferdinand Berthoud showing a mean day rate variation across positions of 0.91 seconds.

There are elements of earlier Ferdinand Berthoud watches in the Naissance d’une Montre 3, including the fusée and chain, but I don’t remember ever seeing all the various elements of this watch – the Guillaume balance; the fusée and chain, the gilt finish and stepped movement cocks, so reminiscent of the work of Berthoud and other late 18th and early 19th century clockmakers – all brought together in the same watch.

Making a watch like this requires a certain amount of stubborness – while I’m sure there is a reasonably healthy margin built into the retail price of each watch, even at CHF 850,000 it doesn’t feel very much like a commercial undertaking. If I had any doubts on the question, there’s that Guillaume balance – I can’t help but wonder if anyone else might take a shot at making one new, from scratch, now that someone’s shown that it can be done. Over the years I’ve pitched the idea of making a high precision watch with a Guillaume balance a few times and the usual reaction has been that it would be prohibitively expensive and also wildly impractical – especially in a modern environment, a plain tempered steel balance spring is just begging to be magnetized, and pretty frequently too. But this is the sort of watch that if you love the history of precision timekeeping and the preservation (and in the case of the Guillame balance, resurrection) of skills in danger of vanishing, that you can just be glad exists. Hooray for anyone who gets one –it’s easily one of the three or four most interesting watches of the year, in terms of horological content – and while I’d like to see one in the metal, I’m happy it’s been brought to life at Ferdinand Berthoud.

The Naissance d’une Montre 3 “Au Temps Qui Instruit” (“To Time, The Great Teacher) Ferdinand Berthoud ref. FB 4BTC.1: case, 18k white gold, 44.30mm x 13mm, water resistance 30 meters. Sapphire crystals front and back; ethical gold certified by the RJC Chain of Custody. Dial, 18k white gold, circular satin finished; hands, blued steel. Movement, caliber FB-BTC.FC, 37.50mm x 8.35mm, running in 37 jewels at 21,600 vph; 50 hour power reserve. Fusée and chain transmission, stop seconds; Guillaume temperature compensating balance; blued carbon steel balance spring with Phillips terminal curve; Swiss lever escapement. Chronometer certified by the COSC. Limited edition of 11 pieces, with two produced per year; price at launch, CHF 850,000.

If you are interested in a really in-depth look at temperature effects in watches and temperature compensation, I highly recommend the articles by David Boettcher: “Middle Temperature Error,” and “Temperature Effects in Watches” which were essential resources for this story. Any mistakes are of course my own. The 1916 Company is an authorized retailer for Chopard watches which is, like Ferdinand Berthoud, part of the Chopard Group. Find out more about the Naissance d’une Montre 3 Ferdinand Berthoud and caliber FB-BTC.FC at FerdinandBerthoud.ch. Find out more about the Time Aeon Foundation at Timeaeon.org.