Some Quality Time With The Grand Seiko Spring Drive UFA

Precision, pursued.

Spring Drive has become so much a part of the modern watchmaking landscape that it’s difficult to see just how unlikely it is. The basic idea behind the technology is obvious only in retrospect: a watch driven by a mainspring, but regulated by a rotating, magnetically braked wheel that also functions as a generator, with the whole thing controlled by a quartz timing package, sounds a bit like a Rube Goldberg machine, The rationale, however, makes the whole thing make more sense, because Spring Drive was originally proposed by its inventor, Yoshikazu Akahane, as a solution to a problem, which is, how do you get quartz accuracy out of a watch, but without using a battery?

Akahane started working at Suwa Seikosha, which is now Seiko Epson, in 1971 and he originally concentrated on battery design, which is ironic inasmuch as Spring Drive was partly inspired by the idea of doing away with batteries altogether. The first patent for the basic idea was granted in 1978; Akahane had gotten the idea for what would become Spring Drive while working on the Seiko Twin Quartz project. Twin Quartz represented one of many experiments taking place in the Japanese watch industry at the time, which were intended to improve the already impressive performance of quartz watches relative to mechanical watches. Twin Quartz was designed as a form of temperature compensation, in which there were two quartz oscillators. The first oscillator acted as the time base, and the second acted as a kind of thermometer, measuring changes in rate as ambient temperature changed; this was used to adjust the rate of the primary time base. Akahane, therefore, was equipped to understand both fundamental problems in precision quartz timekeeping, and to understand the complex issues of power consumption. Many of the early attempts to improve quartz timekeeping precision in both Japan and Switzerland were experiments in high frequency oscillators. Omega’s Marine Chronometer, from 1974, ran at 4,194,304 Hz, versus the 32,768 Hz frequency of a conventional quartz watch, while Citizen developed the Megaquartz, which also debuted in 1974 and which ran at the same frequency. However, the basic problem of battery life remained; both of these watches had a battery life of only about one year.

Akahane’s solution was an ingenious one. Instead of a battery, his Spring Drive movement would have a conventional mainspring, and a conventional going train. The going train would be basically identical to that in a mechanical watch, but there would be no balance and no conventional escapement. Instead, the going train would terminate in a rotor, whose speed of rotation would be controlled by a magnetic brake, with the braking strength in turn controlled by a signal from the quartz timing package. The rotor would also act as a generator, powering the integrated circuit and quartz oscillator. A generator rotor producing an electric current also generates a magnetic field opposing the direction of rotation (in accordance with Lenz’s law) and this is the braking force which is controlled by the IC, using the quartz oscillator as a reference signal.

The first prototype was built in 1982.

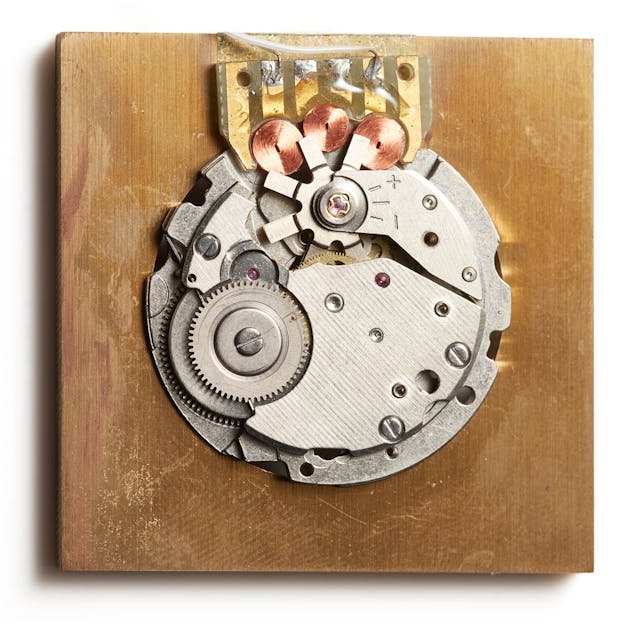

The mainspring barrel’s visible on the lower left, and the Glide Wheel is the eight-armed wheel rotating above the braking and induction coils. The quartz oscillator and integrated circuit are presumably off camera but connected to the coil plate via the soldered wires next to the coils. The prototype ran for just four hours thanks to the power consumption of the IC, and the project was finally put on hold in 1983 pending the development of more efficient integrated circuits. To get a running time of 48 hours, Akahane calculated that an integrated circuit would have to be about 100 times more efficient than those then available.

In 1993, a much more compact prototype was constructed.

This prototype starts to resemble the Spring Drive movements that eventually went into production. In particular, the rotor has been greatly reduced in size; it’s now much closer to the Glide Wheel used in production Spring Drive movements and can be seen under its antishock jewel at about 2:30 on the movement plate. Although running time was still less than 24 hours, significant progress had been made, and in 1997, Akahane succeeded in re-starting the project. A major hurdle was finally overcome when an integrated circuit was developed which recovered energy which had formerly been lost in the braking process (integrated circuit SOI-IC) and finally, in 1999, the first Spring Drive caliber, the hand-wound 7R68, debuted in two Seiko limited editions, and one Credor limited edition, at Baselworld.

This is a little bit the Cliff Notes version. Spring Drive is almost unbelievably efficient; if every person on Earth were wearing one it would generate about enough electricity to light one 100 watt bulb. The Glide Wheel generates just 25 nanowatts of electricity, which is a truly homeopathic amount, and to get there, Akahane and his team made a lot more than two prototypes. The total was closer to 600 prototypes, and this is an example of the single-minded pursuit of improvements in precision in particular, and watch engineering in general, which is very rare; and even rarer to see something like Spring Drive actually make it through development and go into production.

All this is sort of the context behind the development of Spring Drive UFA. Spring Drive precision prior to UFA was not quite at the level of the most precise quartz watches, which are generally capable of precision to within a few seconds’ deviation per year; in the world of mechanical horology, this is basically impossible in mechanical watches although the very best high precision pendulum clocks got there – the Shortt-Synchronome free pendulum clocks could achieve a precision of a second per year, possibly better, and were the first clocks precise enough to detect variations in the Earth’s orbit. These clocks had pendulums which swung in a vacuum; the pendulums were impulsed electromechanically; the rods and weights were made of pre-aged Invar, and they were kept in temperature controlled vaults to eliminate temperature error and physical vibrations. A watch, on the other hand, is constantly in motion, and is subjected to wide variations in temperature and although quartz crystals can reduce the effects of these disturbances, they can’t be eliminated completely. A typical Grand Seiko Spring Drive movement has a precision of ± 10 seconds per month; the goal for Spring Drive UFA – the UFA stands for Ultra Fine Accuracy – was to improve this, to ± 20 seconds per year.

The Grand Seiko UFA was launched in either platinum, or High Intensity Titanium, which is Grand Seiko’s proprietary hardened titanium alloy (titanium is light, strong, and hypoallergenic but it does not, in its usual alloys, take a high polish and it’s also fairly soft; High Intensity Titanium solves both of these problems). The watch is sized in a way that recalls its predecessors, which are Grand Seiko’s VFA, or Very Fine Adjusted, mechanical watches, which were guaranteed to run to a precision of ± two seconds per day, which is a precision seldom matched in mechanical horology even today. The VFA watches were made from 1970 to 1975, and as with Spring Drive, and models like the earlier Twin Quartz, they represent Seiko’s orientation towards and commitment to continued research in improvements in precision timekeeping.

The Spring Drive UFA has all the attributes which have made Grand Seiko, in the global markets which it re-entered in 2010, a cult watch, although the brand has become so popular, especially since its debut as a brand independent from Seiko in 2017, that it can’t really be called a best-kept-secret anymore. Still, it is worth getting up close and personal with a Grand Seiko, from really, anywhere in the company’s price range, for a reminder of why Grand Seiko has earned, and continues to earn, its reputation for attention to detail.

There are very few watches whose dials and hands can stand a real up close look without falling apart just a little qualitatively. Grand Seiko is almost alone in having dials and hands that actually look better the closer you get – the diamond polished markers and hands represent a considerable amount of hand-work, and of course the seconds hand is heat blued, as are all Grand Seiko blued steel seconds hands.

The dial pattern, as is usually the case with Grand Seiko, is nature inspired – in this case, by the Kirigamine Highlands in Nagano prefecture, where Seiko Epson, the home of Spring Drive, is located. The dial is a stylized depiction of the region’s snow covered pine trees, and while knowing the inspiration certainly adds to your appreciation of the dial, the depth, detail, and quality speaks for itself with or without an explicit statement of the connection. The Spring Drive UFA is a recent edition to the Evolution 9 design family, which uses a combination of faceted cases, wide, diamond polished hands, and multifaceted dial markers, anchored by a double wide marker at 12:00. Combined with the ice-crystal geometry of the dial, the effect is extraordinary and on the intersection of fine and decorative arts so characteristic of traditional Japanese design culture as a whole. The crystal-like structure of the dial can be read as stylized snow covered pine trees, but also as an evocation of the quartz crystals whose resonance properties are at the heart of modern, cutting edge high precision timekeeping.

The case and bracelet are finished to the same high standards as the dial and hands, albeit with Grand Seiko the dial and hands are usually the stars of the show. The bracelet and folding clasp are well finished, and of course, the Grand Seiko Spring Drive UFA how has a micro-adjustment mechanism for the dial, which is a feature Grand Seiko fans were very happy to see (it’s a feature that the Grand Seiko collector community had been hoping for, for many years). Grand Seiko continues to use drilled lugs on all its watches (even on the Kodo Constant Force Tourbillon, albeit the holes are tapped for the screws that hold the strap bars in place) and it’s a small but very handy detail which has kept scratches at bay on more than one occasion, during late night strap swapping sessions for Grand Seiko owners.

And inside is the latest offspring of Yoshikazu Akahane’s obsession with marrying quartz precision with mechanical heritage. This is the Grand Seiko Spring Drive caliber 9Rb2, with a 72 hour power reserve, running to a precision of ± 20 seconds per year. The improvement in precision is incremental but significant; it is rare for a new precision standard to be introduced in any series produced watch, especially in the context of a mature technology like Spring Drive, but for Spring Drive enthusiasts, the achievement is meaningful both in and of itself as an improvement in performance, but also in what it says about the fact that at Grand Seiko, precision is never taken for granted and is always, in a positive sense, a work in progress.

The movement has the razor sharp machine applied finish present on most Grand Seiko movements, although as is the case with many newer generation Grand Seiko calibers, the general design feels artistically satisfying as well, with curves and rounded geometries where earlier Grand Seiko movements relied on sharp transitions from horizontal to vertical surfaces. A couple of features are visible through the display back – there is of course, the bronze-colored Glide Wheel, which has at its center the permanent magnet which generates the whisper of voltage that powers the IC and quartz time base. You can also see, just above the Grand Seiko “GS,” a mechanism for adjusting the rate – rate trimmers are rarely found in quartz movements but they allow, as in this case, for fine adjustments to be made to the rate of the watch, should the quartz crystal drift on its frequency over time.

The increase in precision was not due to any single quantum leap, but rather, to a combination of small improvements that added up to a major jump in performance. These steps include the usual pre-aging of quartz crystals for three months, as well as the use of built in temperature compensation. When the quartz timing package is being assembled, the crystal’s changes in frequency over several different temperatures is measured and the information programmed into the IC, with minute changes made to the crystal rate if the temperature changes as measured by an internal thermometer. The temperature sensor and quartz oscillator are then placed in a hermetically sealed chamber in order to protect against moisture, static electricty, and also to protect against sudden extreme changes in temperature. The UFA represents refinement, not revolution, but it also shows just how far refinement can get you.

I spent some time on the development process of Spring Drive, and how much sheer stubborness it took to see the project through from initial concept to actual commercial debut, for several reasons, but one of them is that Akahane did not live to see the commercial and technical success of his invention. The first-pre-production prototypes were shown in 1998, with the commercial release at Baselworld in 1999, but Akahane did not live to see it; he passed away in 1998 at the age of just 52. It’s sad that he didn’t get to see just how far his invention went and that he didn’t see it become, this year, a beacon of pride in the pursuit of precision and a demonstration that watchmaking is still a living art and science. But his idea is still with us, and with the UFA, we all have an opportunity to have a direct physical connection to the man who, a quarter century ago, almost lived to see it happen.

Grand Seiko Spring Drive UFA Evolution 9 Collection: cases, platinum (SLGB001) or High Intensity Titanium (SLGB003); 37mm x 11.4mm, water resistance 10 bar/100 meters; magnetic resistance, 4,800 amperes per meter; box shaped sapphire crystal with AR coating on inner surface; sapphire display back. Movement, Ultra Fine Accuracy 9RB2, Spring Drive automatic, 72 hour power reserve adjusted to ±20 seconds per year. Prices, $39,000 (SLGB001, 80 piece limited edition) or $10,900 (SLGB003).

The 1916 Company is proud to be an authorized Grand Seiko retailer.