Let There Be Light: Why This Is The Golden Age Of Lume

After decades of dangerous and partial solutions, the future of lume has never been brighter.

Luminous materials on watch dials are so ubiquitous today that it’s easy to forget how challenging it was to come up with materials that were safe, efficient and durable. Without modern luminous materials it’s safe to say that the sports watch revolution never would have happened (or at least, it would have happened in a much more dangerous way) and despite the fact that we take them for granted, they are ingenious solutions to a problem watch and clockmakers faced from the very beginning of timekeeping. Today, luminous materials like Super-LumiNova aren’t just for legibility – they’ve become an essential part of the design language of modern watchmaking, thanks to brands like Ressence and MING.

Seeing And Hearing The Time: Sundials And Chimes

The earliest timekeepers we know of were sundials (I suppose before sundials people just looked at the Sun, but the fact that shadows on the ground move as the Sun moves must have been observed very early in human history). The sundial is capable of a precision limited only by the size of the gnomon – the part of the sundial which casts a shadow – but on a cloudy day or at night, of course it is of no use.

The oldest solution in clockmaking was simply to have a clock which could chime the hours; the first clocks were adopted by monasteries, to mark the canonical hours or fixed times of prayer. (There were clocks preceding the European chiming clocks of the 13th and 14th centuries, like Su Song’s Chinese astronomical clock but reading such a clock would have required artificial light – a candle, a torch, a lantern).

Chiming clocks evolved steadily, with the invention of hour, quarter hour, five minute, and minute repeaters and by Breguet’s time, minute repeaters were the definitive technical solution to telling time in the dark. Repeaters have a disadvantage still obvious today – they are complicated, easy to accidentally damage, and fantastically expensive. What was needed was obvious, but obviously impossible – a clock or watch whose dial you could see in the dark.

It was known thousands of years ago that animals could produce “cold light” – Aristotle wrote about sea creatures that glowed in the dark. The idea doesn’t seem to have inspired any real attempts to re-create the phenomenon artificially, although phosphorus, which does glow faintly in the dark, was first isolated successfully in the late 17th century and it is sometimes used for luminous paint today. It’s not widely used as the glow is not as bright as modern luminous pigments; it fades quickly as it requires oxygen to glow, and it’s highly reactive – it can even spontaneously combust, which makes it dangerous to work with.

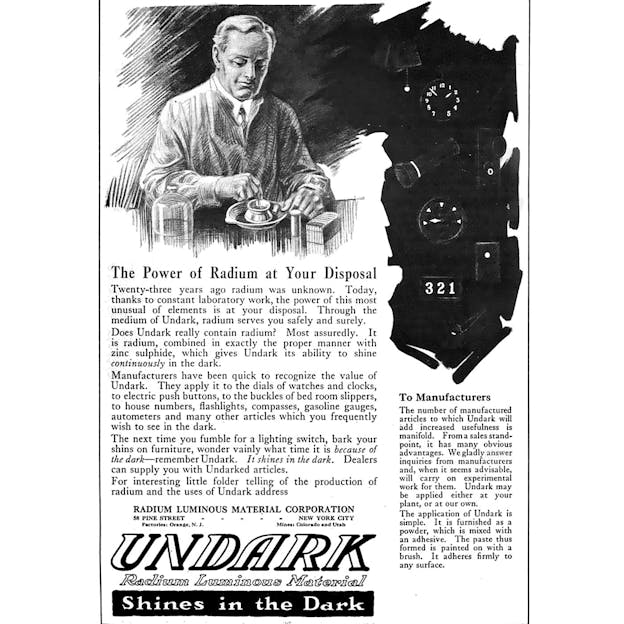

A Dangerous Game: Radium Paint

Given how long even simple organisms have been able to glow in the dark, I guess it’s a little embarrassing how long it took us to come up with the first luminous material for watch and clock dials. That material was radium. Radium is a radioactive element, 88 on the periodic table, discovered by Marie and Pierre Curie in 1898, a discovery for which Marie would pay with her life (she died of radiation induced aplastic anemia, in 1934).

Radium glows only very weakly on its own, but if you mix radium powder with another material that glows when exposed to radiation, you’ve got luminous paint. The material is zinc sulfide, and zinc sulfide was used as a phosphor – a material that emits light when excited by a light or radiation source – in the first generation of luminous paints.

The stuff is dangerous to work with – most serious watch enthusiasts know about the Radium Girls, who painted radium dials for the United States Radium Corporation in the 1920s. They painted dials with radium paint and were encouraged to sharpen the tips of their camel hair brushes with their lips and tongues, and, since they were not warned of radiation hazards, they painted their nails, teeth and faces, for fun. Radium mimics calcium in the body and the Radium Girls absorbed the stuff into their bodies, especially their teeth and jaws and many of them died painfully disfigured.

Radium Watch Dials: Dangerous But Effective

Radium was and is hazardous. Radium dials can be dangerous for centuries – the phosphor, zinc sulfide, is usually burned out by the radiation in anything from a few years to a few decades but radium has a half life of 1600 years. Inhaling radium dust is a hazard of working with vintage radium dials; and a more recently recognized possible danger is that radium decays to radon gas, a known carcinogen. (The relevant study cites “World War II Military Watches” as a possible hazard).

Still, radium dials and hands have some undeniable advantages. They glow brightly, at least until the phosphor burns out, and unlike modern luminous paints, they do not need to be “charged” by light in order to glow in the dark. Their glow does not fade as the night goes by – this is especially advantageous in military applications where you really might need to be able to read the time on your watch as easily at 4AM as at 12PM.

Radium paint had no real competition for decades, despite the risks associated with working with it. But especially in consumer products – and for the safety of watchmakers, dial makers, and watch manufacturers – the hazards of radium paint were clearly an incentive to find a better answer.

The Art Of Compromise: Tritium Dials

The ongoing awareness of the problems associated with working with radium paint let to active research for a safer solution. The next big step forward in luminous paints that could be used in watchmaking was the introduction of tritium, which is a radioactive isotope of hydrogen. Tritium’s first use was in nuclear weapons, in the 1950’s – it’s used to enhance the yield of fission and fusion devices.

Like radium, tritium is radioactive but it’s much safer to use, thanks to its lower levels of radiation and the fact that it primarily emits beta particles, which can be blocked by a layer of cloth or the material of a watch case. It also decays much more quickly than radium – tritium has a half-life of 12.33 years. This makes it much less of a long term hazard. The watch industry began switching over to tritium from radium in the 1960s, and watches with tritium painted dials are usually labeled “T Swiss Made T” or “T<25” (the latter indicates that the radiation emission is less than 25 millicuries). Tritium can also be used in laser-sealed tubes, which are coated on the inside with a phosphor; tritium is still used for gunsights, and self-illuminating exit signs.

The only real problem with tritium other than the fact that it is still a radiation hazard – albeit much less so than radium – is that its short half life means that the glow it emits will diminish noticeably after only a few years. During the tritium era, if a watch was taken in for service on a regular basis this wouldn’t have been an issue as the dial and hands were easily changed for new ones, but the visible decline in brightness remained an issue, as did disposing of tritium parts, which have to be handled as radioactive waste. Like radium paint, tritium paint – or tritium tubes – are self-luminous and at least at first, uniformly luminous through the night, but the search was still on for a less potentially hazardous solution.

Nemoto, Luminova, And Super-LumiNova

Radium and tritium luminous materials – along with other paints based on promethium, which has some of the same advantages and disadvantages as tritium – all work in the same way. The radiation released by the decay of the radioactive material causes an electron in an atom of the phosphor to become temporarily excited to a higher energy level. When the the electron “relaxes” back into its lower energy ground state, it emits a photon, discharging the absorbed extra energy. If the photon is in the visible wavelength, the phosphor glows.

In 1993, however, the material that would come to dominate the industry was discovered, at Nemoto & Co. in Japan. Nemoto had originally been founded by Kenzo Nemoto in 1941, as a luminous paint supplier and had been actively researching safer, non-radioactive materials. One such material was a substance called strontium aluminate. (Aluminates are a group of chemical compounds that contain aluminum and at least one oxygen atom).

Strontium aluminate didn’t come out of nowhere. Researchers at Nemoto, and elsewhere, were experimenting with it, along with other possible materials, as an improvement over zinc sulfide-based luminous paints. Zinc sulfide paints had one big advantage over radium, tritium, and promethium: they were not radioactive. They were, however, not really satisfactory for watch and other instrument dials, partly because their glow was weak and partly because it faded rapidly. Zinc sulfide was a phosphor known from its use in radium paint, and with the addition of copper chloride, it exhibits phosphorescence.

Phosphorescent materials glow in the dark when exposed to light first. They’re related to so-called fluorescent materials, which glow brightly when exposed to light, but don’t have any afterglow (the classic examples were black-light posters, a popular dorm-room decoration in the 1970s). The big difference between the two is that fluorescent materials give up all their stored light energy almost instantly – around 10 nanoseconds, in many cases.

Phosphorescent materials, however, give up stored energy much more slowly. The basic trick is to have a material whose crystal structure can trap stored high energy electrons. These trapped electrons can’t drop down into their lower energy state until random thermal changes free them. As a result, phosphorescent paints can glow for hours after they are excited by light, although the glow steadily fades.

Strontium aluminate, when you add rare earth elements to it (“doping”) like europium and dysprosium, forms a crystal structure in which temporarily charged electrons from the dopants are very efficiently trapped. Strontium aluminate luminous paints are “charged” by ultraviolet light, and emit light in the visible spectrum – green, most often, although other colors can be produced.

Thanks to researchers Yoshihiko Murayama, Nobuyoshi Takeuchi, Yasumitsu Aoki and Takashi Matsuzawa, Nemoto was granted a patent for its new luminous material in 1994. And, in 1998, Nemoto formed a joint venture with RC Tritec AG. RC Tritec was founded under the name Radium Chemie Zeller in 1934, and had been a producer of radium, and then tritium based, luminous pigments for the Swiss watch industry.

Making Magic: How Super-LumiNova Is Made

Strontium aluminate is technically a ceramic, and turning raw materials into Super-LumiNova is a highly complicated process. It begins with taking the raw material and baking it in a kiln at 1500 degrees Celsius, the powdered raw materials having been carefully purified first as any contamination will prevent the correct crystal structure from forming.

The raw powder is not luminous, but the firing process causes the powders to fuse and form a new crystal structure and it is at this point that it starts to exhibit phosphorescence. The fired ceramic material emerges from the kiln in rough blocks.

The next step is grinding the blocks into a fine enough powder to use in pigments. The grinding process is slow, and at every step care has to be taken to avoid contamination and to ensure the blocks are ground into powder of a uniform consistency. Strontium aluminate is extremely hard – 9 on the Mohs scale; diamond is 10 – which is one of the reasons it was thought at first that it wouldn’t be usable as a pigment base, until the manufacturing problems were sorted out.

Once the ground pigments are sieved and sorted by grain size, they are controlled for light output and color. (For a look inside RC Tritec, check out the article, “Making Swiss Super-LumiNova” at The Naked Watchmaker).

RC Tritec can make SLN in various grades; currently the highest grade, with the longest afterglow and strongest emission is SLN X2. They can make SLN in just about any Pantone color but the strength of the afterglow changes depending on the color of the pigment – green glows most brightly; dark red is the most dim.

The same basic material is available outside Switzerland under other proprietary names, like LumiBrite, but the basic chemistry and physics of light emission is the same.

Super-LumiNova And The Future Of Watch Design

How bright will your watch actually glow? That depends on the grade of Super-LumiNova used, and the thickness with which it’s applied. Thicker generally means brighter although there is a law of diminishing returns – once you get past a certain thickness, the upper levels of the pigment absorb so much UV light that the lower levels don’t charge properly. As a rule though, the more lume (in both depth and width) the better.

Super-LumiNova – and by that we mean, generically, all strontium aluminate luminous materials – is a nearly ideal solution to the old problem of telling time at night. It is completely non-radioactive; the afterglow it produces, if properly charged, is long-lasting, albeit it fades over time; and perhaps most importantly, it appears to last indefinitely; it can be charged repeatedly with no loss of photoluminescence at all.

The only caveats seem to be that it can be damaged by prolonged exposure to high humidity or direct exposure to moisture but then, that’s true of most of the innards of a watch.

That durability and permanence means that lume can be used as a design element in ways that would not have been possible before the advent of strontium aluminate based luminous material. It can be incorporated into bezel and even watch cases (as IWC has done) and it can be used as an intrinsic design feature as well, with no fear of fading or deterioration.

One of the most notable users of lume as a design element today is probably MING, for whom lume is essential in every design from the original 17.01 up to the latest 20.01. The latter has a laser etched sapphire dial with 600 individual “voids” each one of which is filled by hand with Super-LumiNova, and the effect is something that even Breguet would not have imagined in his wildest dreams.